Zhejiang Conceptfe New Material Technology Co., Ltd. is one of the earliest enterprises in China to carry out research, development and industrialization of fluoropolymer materials and their applications, holding a leading position internationally, with an annual production capacity of5000tons of high-performance engineering materials. From a single product in the early days of its establishment to diversified products today, the company has evolved from a simple supplier ofPTFEraw material products to a one-stop solution provider for various special engineering materials.

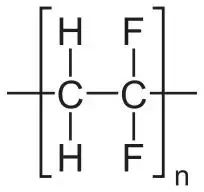

Following the successful launch of thePEEKseries products, Conceptfe has successfully introduced another special engineering plastic - the second most produced product among fluoroplastics - polyvinylidene fluoride, abbreviated asPVDF.

Product Introduction

PVDFis formed by free radical polymerization ofVDFmonomers. It is a thermoplastic engineering plastic with excellent comprehensive properties, wide applications, and characteristics of fluoroplastics.

Due to its gap-free spatial barrier, no atoms or groups can penetrate its structure to damage the carbon chain, thus exhibiting extremely high chemical and thermal stability.

In addition,PVDFhas excellent resistance to oxidation, ultraviolet rays, and high-temperature radiation, as well as good tensile and impact strength, high hardness, wear resistance, high heat distortion temperature, and excellent creep and fatigue resistance. Its service temperature range is-60~150℃,making it a strong and tough structural material.

Product Raw Materials

The main traditional global manufacturers of polyvinylidene fluoride (PVDF) include Arkema, Solvay, Sanaifu New Materials, and Dongyue Group, etc.

Product Applications

Based on the excellent properties ofPVDF,its applications are mainly divided into industries such as petrochemicals, pan-semiconductors, electronics and electricals, and coatings.

Petrochemical Industry

PVDFhas excellent chemical resistance and processability, as well as resistance to fatigue and creep. Therefore,PVDFis widely used in fluid handling systems of petrochemical and other industrial equipment, including pumps, valves, pipes, pipe fittings, storage tanks, etc., as a whole or lining.

Pan-Semiconductor Industry

Pan-semiconductor manufacturing has extremely high requirements for the material properties of related equipment, mainly including roughness, chemical stability, and electrical insulation.PVDFis widely used in production process equipment for semiconductor and photovoltaic industries, such as storage containers for high-purity chemicals, conveying valves, pipes, and pipe fittings, due to its good chemical stability, electrical insulation, and flame retardancy.

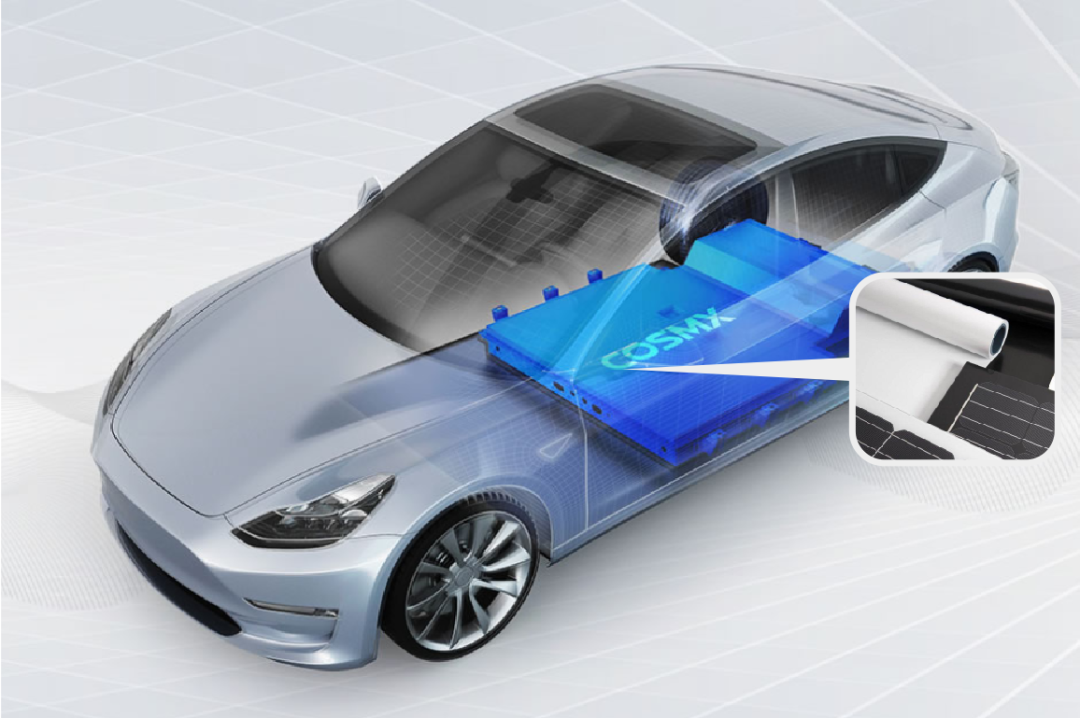

Electronics and Electrical Industry

PVDFhas insulation, corrosion resistance, self-extinguishing property, aging resistance, and easy processability, and can be used to manufacture special wires and cables, connectors, sheaths, cathodic protection sleeves, etc. In addition,PVDFhas excellent corrosion resistance and chemical stability. Porous membranes, gels, separators, etc., made ofPVDFresin are applied in lithium batteries, photovoltaic backsheet films, etc.,for manufacturing potassium battery separators and separator coatings.

Coatings Industry

PVDFis one of the main raw materials for fluorocarbon coatings. Due to the super weather resistance ofPVDFresin, which allows long-term outdoor use, such coatings are widely applied in outdoor buildings, such as power stations, airports, highways, high-rise buildings, etc.

Other Industries

PVDFcan be used to produce various porous and non-porous materials, applicable in the field of biomedical devices.PVDFhollow fiber membranes can be used in water treatment.

Conceptfe Products

CONCE®PVDFproduct series include plates, rods, welding rods, etc., with multiple specifications and rich varieties.CONCE®PVDFproducts balance performance and color. Selected brand raw materials and strict control of all production links ensure product quality. The products have passedRoHSandREACHcertifications. Conceptfe products have outstanding advantages:

01

Good dimensional stability, excellent mechanical properties, and outstanding processability. Optimized production processes ensure product quality.

02

High batch stability and traceability.

03

Strong development capabilities to collaborate with customers on development projects.

04

Complete mold specifications, accepting customized production according to customer needs

Note: For detailed product dimensions, please consult separately.

(The above images are all from the internet. Please contact us immediately for deletion if any infringement is found.)

.png)

.png)